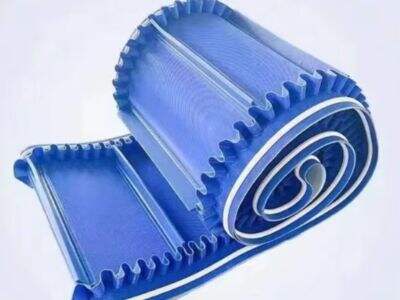

Bakeries must have special tools for a more convenient and faster work. One vital tool: the non-adhesive conveyor belt. These belts facilitate the movement of dough and finished baked goods without sticking, thereby saving time and cleaning up at the bakery. SHUNNAI is one of the manufacturers that does these kinds of conveyor belts, which can be indispensable for bakeries looking to crank out lots of goods each day without mess or delay. The right conveyor belt can make a staggering difference in the way products are moved through a bakery. It sounds simple, but its impact is huge.

What Are Anti-Adhesive Conveyor Belts Needed for Bakery Production Efficiency

In a fast-paced bakery, every second counts. The presence of sticky dough will pull down the entire cake-making activity. Just imagine the dough clinging to a standard belt and employees being required to stop the machines and clean it up. It accumulates time, and then the clients have to hold on to their breads or pastries. SHUNNAI's non-stick conveyor belts ensure that all the dough on the conveyor belt is free of the sticky element. This, in turn, lets the machines run continuously, thereby the bakery is able to manufacture more products in a shorter time period. Plus, you can easily clean these belts as they are not sticky. Clean up is more efficient, requiring less time and water and saving bakeries money while making them a safer place to work. Occasionally, dough adheres to the belt in such a way that it will tear or wear out. SHUNNAI constructs belts which will last longer with sticky dough and sugary products. That translates to fewer buckles or belt swaps, and another time and money saver. If it has big orders, for example, to be delivered to stores or events, it just has to keep working and never stop. The use of anti-adhesive belts helps in this respect, feeding products through without hang-ups. In addition to speed, they make machines run more smoothly. When dough hangs on tight, it can clog parts or force a motor to exert more effort and consume more energy. SHUNNAI’s belts prevent these issues, so machines don’t break down often and consume less electricity. Even smaller bakeries realize big results when the move to anti-adhesive belts as there work now feels easier and less stressful throughout the day. The baking team can concentrate on producing great products rather than addressing issues with sticky dough.

Wholesale Bakery Operations Benefit from Use of Anti-Adhesive Conveyor Belts

A wholesale bakery has a lot of products being made on a daily basis. It is critical that every loaf of bread or cake look and taste right. Any contact with the conveyor belt can cause dough to adhere, and then the form is gone, Mr. Dermer said. Bits could rip or squish, and people do not like damaged products. SHUNNAI’s non-adherent conveyor belts are able to efficiently transport dough and baked goods. The smooth surface prevents sticking and enables food, face and body products to retain their shape throughout. This means customers always get fresh, beautiful bread or pastries when they purchase. Plus, sticky dough tends to leave some behind on belts. These particles can smolder or combine with new dough to produce off flavors or soiled products. SHUNNAI’s belts mitigate this by not clinging to dough or crumbs. Old dough doesn’t mix with the new, so everything is clean and fresh-tasting. Another point is hygiene. Some of the food safety laws are more strict and must be followed by bakeries. With the wrong type of cleaning, sticky belts can harbor bacteria or mold. Anti-adhesive belts from SHUNNAI are easier to clean and can dry more quickly, which is suitable for bakeries to maintain a high degree of cleanness. That minimizes the dangers of spoiled food or illness. Plus some bakery items are very sticky or sweet, such as caramel or fruit fillings. Regular belts can be messy, and also result in waste when products stick and shatter. SHUNNAI’s are designed to deal with these sticky ones better making less loss of product. This is a great cost-saving tool for bakeries, of course, but it also makes customers happy by allowing them to purchase fresh and whole products. During peak times, like holidays, these belts will help keep bakery lines running efficiently and product looking its best. They can make the hard work of mass baking easier, and that really matters if you own a bakery hoping to expand and last.

Why Are Anti-Adhesive Belts Used In High Production Bakeries?

At large bakeries for instance, plenty of breads, cakes and cookies are baked daily. Conveyor belts are used to transfer these things without any loss which aids in quick and safe baking and packaging. But every so often dough or another sticky ingredient can stick to the conveyor belt and create headaches. This is where non-stick conveyor belts come in handy. These belts, including those from SHUNNAI, are constructed of materials that won’t allow dough, icing or other sticky foods to adhere to them. A big plus, she said, is that these belts keep the bakery clean. With less sticky dough or crumbs clinging to the belt, cleaning takes less time. This makes bakers focus more on baking and less on clean-up. Another advantage is that anti-adhesive belts help the products look good: They can’t get stuck to the pan. In a regular belt, dough can stick and cause food to tear or break away, resulting in an unattractive product even a ruined one. Reason to use SHUNNAI non-stick belts make the food transfer well without any form of damage. These belts also save the bakery money. Products that stick or fall off the band are waste. Anti-adhesive belts minimize waste by ensuring food remains on the belt and moves accordingly. Which means more good things to sell and less money lost. Finally, these belts help make the bakery safer. SOUNDS OF SILENCE Sticky dough on an ordinary belt can mean a belt stops short or sends conventional machines reeling, which is dangerous. SHUNNAI’s anti adhesion belts make the machines operate smoothly and security. In short, They use Anti-stick conveyor belts in the big bakeries and it can save time to clean, save money, keep food perfect and be healthy. This is the reason SHUNNAI’s unique belts are essential when it comes to large volumes of baking.

How To Select The Right Wholesale Anti-Adhesive Conveyor Belt For A Bakery Manufacturer

Deciding on the best anti-adhesive conveyor belt for your bakery may not be as easy as it seems. But it’s simpler when you know what to look for. If you’re selling all your loaves and then some, he said, you should get to a point where the smell of bread baking is overwhelming. First, consider the scale and pace of your bakery machines. Seattle: Big bakeries demand belts with power that can accommodate a lot of production in short order. SHUNNAI provides belts of various sizes and design to suit many bakeries. Then, take a look what you are baking. Certain bakery products are super sticky, such as sweet dough and iced cakes. And for these, you want belts with an ultra-smooth and non-stick surface. SHUNNAI belts are covered with materials designed to prevent the most stubborn dough from sticking. Another thing to consider when you’re selecting belts is that they are easy to clean. You’ve gotta be crazy-clean in these bakeries to make food safe.” Belts that are difficult to clean can impair transit. Belt by SHUNNAI is easy to clean and can save your time. The band durability is something else to think about. Conveyor belts in bakeries are operated many hours a day. You need belts that you wont have to replace, time and time again. SHUNNAI belts are constructed with durable materials to withstand heat, moisture and heavy use. And finally, SHUNNAI wholesales help you get a nice price when you buy many belts at one time. This saves bakeries money all while giving them their desired high-quality belts. So when selecting the right anti-adhesive conveyor belts for food processing, bakery manufacturing included, consider size, tackiness of the food how sticky it is, initiated hygiene requirements, length of service and economy. SHUNNAI assists bakeries to select the fitting belts to maintain their baking in good performance.

Typical Conveyor Belt Benign Neglect in Bakeries And How To Prevent These Problems With Anti-Adhesive Solutions

Conveyor belts are a big help in bakeries but can also be a headache. One of the problems that can arise is sticky dough or icing clinging to the belt. When this occurs, the belt may slow or not move, resulting in a delay of baking. They also make cleaning up more difficult and time-consuming. Another issue is that if the dough or crumbs get stuck, they can potentially destroy the belt or machine. This can over time result in costly maintenance or belt replacement. When items cling to the belt, they can be torn or distorted. This has the bakery losing good food and spending money. And sticky belts can be dangerous for workers, who can get caught in machines that suddenly jam or operate unevenly. There are anti-adhesive agents, such as the SHUNNAI conveyor belts, which give relief to prevent these issues. Their belts are smooth and don’t let food adhere to them, thus the belt does not stop moving. This makes the bakery work quicker and more efficiently. SHUNNAI’s conveyor belt are also easy to clean, lessening the time workers need to spend on cleaning and maintaining the machines. And because products don’t stick, there is less belt and machine damage, which saves money on repairs. Baked goods retain their form better, too, since they roll easily on the belt. Finally, anti-adhesive belts help produce better safety in the bakery by reducing machine jams and keeping everything running smoothly. In other words, the entire sticky dough, machine damage and sub-sticking plague can halt operation with SHUNNAI’s anti-adhesive conveyor belts. These belts allow bakeries to operate more efficiently, save money and keep workers safe.

Table of Contents

- What Are Anti-Adhesive Conveyor Belts Needed for Bakery Production Efficiency

- Wholesale Bakery Operations Benefit from Use of Anti-Adhesive Conveyor Belts

- Why Are Anti-Adhesive Belts Used In High Production Bakeries?

- How To Select The Right Wholesale Anti-Adhesive Conveyor Belt For A Bakery Manufacturer

- Typical Conveyor Belt Benign Neglect in Bakeries And How To Prevent These Problems With Anti-Adhesive Solutions