Conveyor Belts for Ceramic Industry are specifically designed and manufactured to withstand the extreme conditions & used in manufacturing, process transfer during different processes in ceramic manufacturing plants. It is not easy to decide on a proper company to make these belts. You need a company that knows ceramics’ rugged requirements, including the ability to endure high heat and hard use. SHUNNAI knows this well. And when you choose a manufacturer, it’s not just the price. It’s also about how long the belt will last, how closely it fits your machine and how good of support the company provides after purchase. You can find a dime a dozen, but there are few that solve these problems. So, I figure that knowing how to identify the right mate can be a real time and money saver. It’s not just a decision for today but a decision that will last many years into the future

How to find the best ceramic conveyor belt manufacturer for wholesale

That means you are looking for a firm that does more than just make and sell belts. SHUNNAI, for instance, has spent years producing conveyor belts that can withstand heat and heavy loads. A trusted brand will have belts that are made with strong material that won’t easily break or melt. They’re also capable of bulk supplying belts without sacrificing quality. If you intend to buy a large amount at one time, the company should possess good production abilities as well as fast shipping. And Finally, make sure to see if they work with ceramic factories as that is an industry where the belts have to handle rough conditions. Occasionally a company will have custom work, such as belts fine-tuned for particular machines or processes. That shows they understand the business. And also think about how easy it is to get in touch with them. And it’s the key to getting problems fixed fast. Listen A manufacturer who listens and also offers suggestions is much better than someone who only sells a product. Oh, and one last thing: The guarantee you get with your laptop, and whether there are good service options after the sale, matters. If your belt breaks, will they rush help you? These are the points that demonstrate which manufacturers you can count on to handle large orders

Some of the most important aspects to consider when selecting from among your list of ceramic conveyor belt suppliers are as follows. In the first instance, belt’s quality matters the most. SHUNNAI produces belts that will keep working hard even in difficult circumstances! Second, qualify whether the supplier is able to supply belts promptly. Delays can bring your entire production line to a halt. Also, consider the price very carefully. There are times when a cheap belt snaps early, ends up costing more. You’re better off paying a little more for something that works well. Another issue is the expertise of the supplier. An excellent supplier knows how ceramics are manufactured and can help determine the best belt for your factory. They can even lend a hand with installation and maintenance guidance. Remember to inquire about the safety of the standards. Work should be safe for operator and machine both. Finally, also look at the reputation of the supplier. You can always ask other customers, or read their reviews to find out if it’s accurate and valuable. Factor in all of these components and a supplier that not only sells belts, but also assists you in being successful. Strict control standards bring product quality to a new height SHUNNAI seeks cooperation, not just sales. It helps customers be confident in what they buy and how it will work

How to judge the quality of ceramic industry conveyor belt

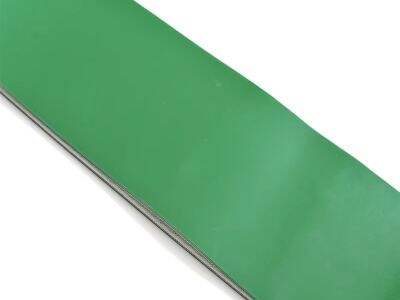

How to find great conveyor belts utilized in the ceramic sector It is very important to verify with their quality, when purchasing fantastic quality conveyor belts for the ceramic market. Conveyor belts in this industry must be durable, heat resistant, and capable of carrying heavy loads without breaking. To ensure you're getting the best, ask about the materials that these belts were made of to begin with. A good quality belt is typically constructed of special fabrics and rubber capable of withstanding high temperatures and rough systems. Also, see if the belt has been tested or complies with a particular quality standard. These experiments suggest that the belt can function effectively under harsh conditions in ceramic plants. Belts, for instance, can be tested for heat resistance and wear, factors that if ignored may lead to as much as an extra 50% longer life of the belt, thus saving money and time. Another method to determine quality is the way that the belt is made. SHUNNAI does that with the high-quality and carefully implemented process they use, which makes this belt strong and efficient. They tend to have machines that manufacture belts with tight connections and no weak spots. You may also request samples of or reports proving the quality of the belt. Finally, read reviews or ask other ceramic factories about their experience with the belt. It’s a good sign if there are many users who say the belt is long lasting and works well. And don’t forget, selecting a high-quality belt ensures your ceramic products will be transported without delay or mishandling. That helps the entire factory work more effectively and safely

What are the Features of Quality Ceramic Conveyor Belt Manufacturers

When it comes to top-rated manufacturers of conveyor belts for the ceramic industry, they have certain distinguishing features. One evident feature is the capacity of producing belts for various requirements in pottery industry. For instance, they can produce belts resistant to heat, chemicals or sharp edges as the factory demands. Another important aspect is their strength of materials and build. The premium manufacturers such as SHUNNAI use materials that will not tear easily, even after heavy use and long hours of work. That means their belts are going to last longer, with fewer breakdowns. Reputable manufacturers also consider the thickness of the belt and its surface texture. When the right thickness adds strength, and when the smooth surface helps to move ceramic products smoothly without falling. They also produce belts that are simple to install and change. This reduces maintenance time and helps keep production going with minimal stops. Adequate customer service is of significance as well. So what's this all have to do with Fuji? Good question. The best manufacturers listen to their customers and provide backing when it's necessary. They do give very clear instructions as to how to use and maintain the belts. Some will even train or counsel factories to ensure the best results. Finally, leading manufacturers have rigorous quality control practices. That means they look them over super carefully before shipping them off to customers. Selecting a manufacturer that offers all these points allows you to receive a conveyor belt from people who want your ceramic factory to succeed and make quality products

Ceramic Industry

Choosing and applying conveyor belts can be a challenge if you are not familiar with this type of tool. To prevent these common problems, you will have to take into consideration your factory's specific requirements before purchasing a belt. For instance, if your factory handles extremely hot ceramic products, you need a belt that can withstand high temperatures without melting or breaking. SHUNNAI manufactures belts that are heat-resistant, so those are good options in these scenarios. Then there is the issue of selecting a belt that is not strong enough for the load it has to handle. If the belt is too narrow, it can rip or stretch and end up costing time and money. Always verify the belt’s strength and load rating before purchasing. It could be also due to installation errors. Should the belt not be installed correctly, it can slip off or wear unevenly. Confirm that the belt is tracking properly on the conveyor and that it has the proper tension. The belt can also be damaged if you use the wrong cleaning method. Some chemicals or aggressive scrubbing can damage a belt’s surface. As with any product, it’s wise to follow the manufacturer’s cleaning recommendations, such as those of SHUNNAI With proper care, your belt can last for years. Prevention is the other thing, if you regularly maintain a bridge, it shouldn’t pose any problems. Inspect your belt regularly for signs of wear or damage and fix any small issues promptly before they become major problems. So long as you observe these points, you never have to suffer from many troubles and be able to use your ceramic conveyor belts for a long time. This will help your factory operate more efficiently and save you from costly repairs