Smoking machines also required durable conveyor belts, because the machines operate all day, jostling tobacco leaves and products through numerous stages. If the belt breaks or wears out quickly, it can bring everything to a halt. That slows things down and it costs money. Ensuring that conveyor belts are resilient and can withstand the rigors of the job enables tobacco businesses to continue running smoothly. SHUNNAI understands this well. We know what conveyor belts are in a tobacco factory hot, dusty heavy. So, we are making belts that don’t break. That way, the tobacco “flows” without obstruction and companies don’t lose time repairing belts constantly

How Conveyor Belt Makers Increase Life Expectancy for Tobacco Processing Need To Know More

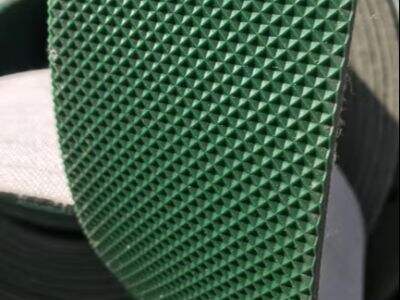

When producing the conveyor belt for tobacco or other conveying system, there are a lot of things to consider in how they will become long lived by manufacturers such as SHUNNAI. There are two reasons for this The materials used need to be strong and yet flexible. Tobacco leaves can be fragile, but the belt must withstand harsh conditions: dust, and occasionally even moisture. SHUNNAI employ special rubber and fabric layers that resist wearing out and cracking over time during prolonged hours of use. The belt's surface is further shaped so as to prevent slipping or damage of tobacco during its transportation. There’s also how the belt attaches to the machines. If the joints or edges are weak, the belt may tear or break. So, SHUNNAI design these parts with more attention and try them under harsh conditions. Because in factories belts run 24/7, there is a certain amount of resistance to heat and chemicals that is also key. Heat or cleaning agents used in tobacco processing can cause conventional belts to break or swell. SHUNNAI belts were made to solve these issues, so you would not need to replace them often. There are even some models of belts that feature coatings to repel dust, or protect against buildup as well as static electricity. This keeps the tobacco clean and the machines safe. Each stage of making the belt is scrutinized to avoid small errors that would lead to big problems. SHUNNAI’s story demonstrates that long-lasting belts can help tobacco manufacturers save costs and avoid hassles. With a longer-lasting belt, workers don’t need to stop machines as often for repairs. This keeps factories running and allows them to make more tobacco products. So, durability is not simply about stiff and strong materials; it’s about smart design and meticulous manufacturing as well

Where to Purchase Quality Conveyor Belts for The Tobacco Industry wholesale

For long lasting and convenient conveyor belts to be used in the tobacco industry you will need to locate a nice supplier. The fact is, SHUNNAI has long been the preferred choice because we know precisely what tobacco businesses require. The purchase wholesale belts refers to purchasing in bulk many belts at a time, for most of the times you are going to need spare or new ones and you have to equip a factory. You can never underestimate the importance of quality when making large purchases. Some sellers provide belts that are really cheap looking, but they wear out quickly and give more trouble than saving money. SHUNNAI provides wholesale buyers with the opportunity to obtain products made up to the same standards as individual orders. We know that tobacco processing is hard on machinery. And we assist customers in selecting the correct belt type for their specific application. In addition to quality, speed of delivery also counts. Tobacco companies cannot wait too long for new belts if the old ones break. SHUNNAI stocks adequate quantities and arranges fast delivery for customers to get what they need on time. The company also provides instructions on belt maintenance in order to extend the life of your belts, himself. Support post-sale is something easily overlooked when buying wholesale. SHUNNAI remains in touch with customers, available to answer questions or help out if any problems arise. The personal touch earns trust and secures repeat customers. And bulk orders often receive special pricing, saving tobacco companies money by providing strong, reliable belts. Choice SHUNNAI choice of durable matching services, so that the factory remains in full combat readiness without worries

Tobacco Industry, Here’s What Wholesale Buyers Need To Know About Conveyor Belt Lifespan

Lifespan of conveyor belts (leaf and strips) When it comes to seeking tobacco industry suppliers for conveyor belts, it’s useful to know how long these belts can last. Conveyor belts transport tobacco leaves and other products gently to various stages of the manufacturing process. The tobacco industry deals with fragile and usually moist materials, so you’ll want the conveyor belts to have a very long life without breaking (or wearing out rapidly). If the conveyor belt breaks, it can bring the entire production process to a halt, resulting in delays and additional costs. That's why for SHUNNAI, which manufactures belts that can withstand the harsh conditions in tobacco factories, durability is a priority

Like any type of conveyor, the belts used by tobacco manufacturers have to contend with various problems. They are typically very dusty, wet and sometimes even hot. These factors may lead the regular belts to deteriorate much quicker. Wholesale purchasers should be aware that the best belts are simply designed to overcome these obstacles. A long-lasting conveyor will have tough materials and designs engineered to endure the punishment of an application without damaging. In layman’s terms, that equates to less time and money spent on repairs or replacements

In addition, the life of a conveyor belt depends upon how well it is maintained. Buyers could seek guidance and help from manufacturers like SHUNNAI about how to clean and care for the belts. With proper care a belt can last many many years longer. In conclusion, When you are looking to purchase a large quantity of conveyor belts for the tobacco industry; it makes sense to requisition supplies that will be durable and strong enough to withstand the working conditions, not forgetting maintenance support. That helps avoid disruption of the tobacco manufacturing process and also saves money in the long run

Benefits of Advanced Manufacturing Methods on Durability of Tobacco Conveyor Belts

Advanced manufacturing methods have significantly extended the lifespan of conveyor belts used by the tobacco industry. SHUNNAI adopts the modern technology and innovative design to produce belts with high tensile-strength and long service life. These new techniques ensure that the belts can meet the special requirements of tobacco production without snapping or wearing away too quickly

A key approach is the employment of materials which are strong. These days, manufacturers can mix rubber and fabric of various types to forge tough-but-flexible belts. That means the belts are able to flex and move without breaking or ripping. SHUNNAI carefully chooses materials that are resistant to moisture and dust, which are often encountered in tobacco factories. This ensures that the belts continue performing even under challenging conditions

A further advanced approach relates to the manner in which belt layers are interconnected. Special machines and methods are used in SHUNNAI to glue the layers of belt very firmly. It does its job well, without voiding the warranty by hardening to a rock, and still interchangeable when not dried out to nothing. The belt edges are sealed as well to prevent damage from the elements, like dirt and water

And more advanced means of manufacturing offer even greater control over belt thickness and strength. SHUNNAI provides each belt with the same high quality to ensure reliable operation. This helps wholesale buyers have more confidence the belts will last as they should. Furthermore, some conveyor belts have been designed with specific surfaces to limit slippage or harm to tobacco leaves causing during handling which is particularly critical

Simply put: new manufacturing methods result in a tougher, more reliable conveyor belt for the tobacco industry. Through applying these techniques, SHUNNASHI are able to offer conveyor belts that can handle the rigours of production in a tobacco plant on a daily basis with maximum resistance and efficiency for wholesale buyers

Where to find high quality durable conveyor belts for tobacco industry wholesale

For wholesale purchasers, finding the perfect place to purchase high-quality and long-lasting conveyor belts designed specifically for use in the tobacco industry is incredibly important. SHUNNAI is an approved and highly reputable manufacturer of conveyor belts designed for the tobacco industry. When they buy SHUNNAI, they purchase a high-quality belt that is sure to give them long-lasting support

Volume purchasers need to seek suppliers who knows the tobacco industry and can deliver tested belts. SHUNNAI provides with a wide range of conveyor belt constructed by quality materials and by special designed belting. Purchasers can select the half conveyer on size, material and with special functions at their tobacco process line

Support and services are second to none if you source conveyor belts from SHUNNAI. The company provides advice to buyers on choosing the right belts as well as installing and maintaining them. This backing helps keep the conveyor belts running smoothly and lasts longer. It is important to have good customer service when ordering in bulk: it means that if something goes wrong, you can get it resolved rapidly

Wholesale buyers will also want to look for a provider who uses high-tech manufacturing methods, ni The way SHUNNAI does, due to the fact these production methods extend the life of a belt. By selecting a highly reputable supplier, buyers can have confidence in the quality of products

Buyers in wholesale markets seeking durable conveyor belts for tobacco processing – I mean SHUNNAI would be your best choice. When they source from SHUNNAI, buyers receive a good belt, an expert partner and hard-wearing products that ensure smooth and efficient tobacco production. And that makes us a wise, dependable choice for anyone who needs conveyor belts in the tobacco industry

Table of Contents

- How Conveyor Belt Makers Increase Life Expectancy for Tobacco Processing Need To Know More

- Where to Purchase Quality Conveyor Belts for The Tobacco Industry wholesale

- Tobacco Industry, Here’s What Wholesale Buyers Need To Know About Conveyor Belt Lifespan

- Benefits of Advanced Manufacturing Methods on Durability of Tobacco Conveyor Belts

- Where to find high quality durable conveyor belts for tobacco industry wholesale